We are one of the few vertically integrated companies, starting from the production of blocks, then moving on to block transformation into slabs using our own equipment, and concluding with the creation of custom-sized cuts using state-of-the-art CNC milling machines.

Manufacture

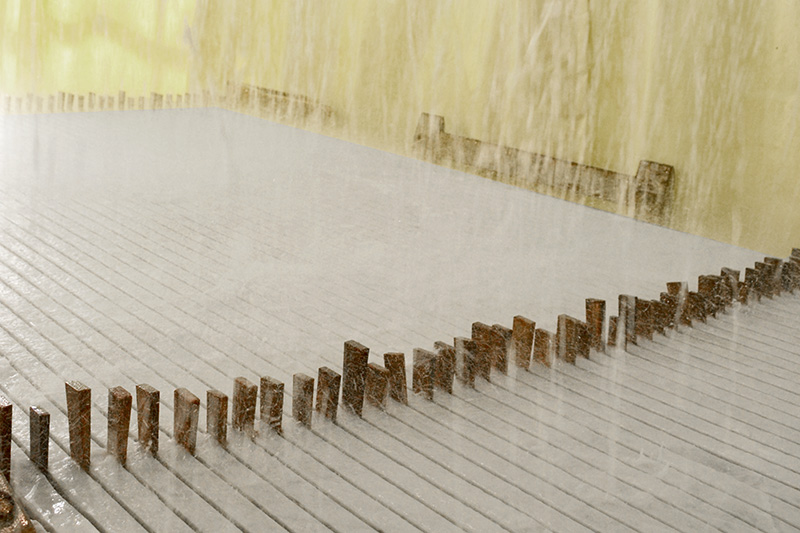

We realize all types of finishes: sandblasted, bush-hammered, honed, polished, grooved, waterjet, brushed, flamed, and we are open to exploring new ones

For years at Euromarble, we have patented a new way of working that allows the customer to see the finished project even before any cutting operation takes place. This ensures further enhancement of quality during the implementation phase and allows us to develop each project even more in line with the customer’s ideas and requirements.